Wheels of change

The process of industrial transformation using automation is gathering momentum across the country

With rapid economic development and urbanization, it has become increasingly difficult to find cheap labor in China's coastal areas. Rising labor costs have affected many labor-intensive enterprises, thereby sparking global concerns.

Considering the rising costs of capital, labor, natural resources and other production indicators, some enterprises have started to upgrade manufacturing technologies and buy advanced equipment, thereby elevating their production to a higher automation level. These enterprises have also gradually increased capital inputs and investment in technology and management to deal with the impact from rising labor costs.

The developments indicate that factory automation using new technology is vital for development of enterprises and industry. The progress achieved on the automation front has helped China to upgrade industrially, with the focus shifting from labor-intensive to technology and capital oriented.

Over the last 30 years, China, with its distinct advantage of cheap labor, has rapidly become the "world factory". Earlier research shows that labor efficiency of manufacturing in China is 1/16 of that in the UK and 1/18 of that in the United States, while average salaries are 1/27 and 1/21 respectively.

Labor costs have been lower compared with those of other developing countries. Labor efficiency in China is nearly three times that of India, but average salary is only twice more than India's.

For a long period, the Chinese economy has been driven by rapid development of the labor-intensive manufacturing industry along with a superfluous cheap labor force. But such development models can neither exert pressure nor motivate the industry to go for technological upgrades.

However, it is important now for enterprises to improve production automation, especially as labor costs are rising.

Different industrial sectors will gradually improve the automation process and that will lead to the development of an advanced manufacturing industry. The differences in technologies and the structure of capital input across various sectors will determine when higher automation is applied.

The bigger the labor costs are, the more the need for such moves, with better profits being the underlying factor. In other words, businesses that require more labor but with lower automation process are more prone to higher labor costs and more inclined to adapt technology faster.

Automation levels will gradually improve from east to west as manufacturing in China moves into top gear. Since China has large land areas and a huge population, the gap in industrial development between regions is large.

The eastern region, which has benefited from the reform and opening-up policy, has enjoyed a higher degree of economic growth and has seen a rapid increase in land and labor costs. The central and western areas are less developed, rich in labor resources and with lower land costs.

Under such circumstances, enterprises in the eastern areas will shift labor-intensive manufacturing operations to the central and western regions. They will focus more on technology innovation to improve output and thus herald industrial transformation.

Over time, the automation process will spread gradually to the whole manufacturing industry and lead to an industrial escalation that will allow the coexistence of advanced and traditional manufacturing industries, and the coexistence of labor-intensive and input- and technology-intensive enterprises. So China's manufacturing will be able to take advantage of the low labor cost regime for some more time.

The author is an associate researcher with the China Development Institute.

(China Daily 10/07/2011 page7)

Today's Top News

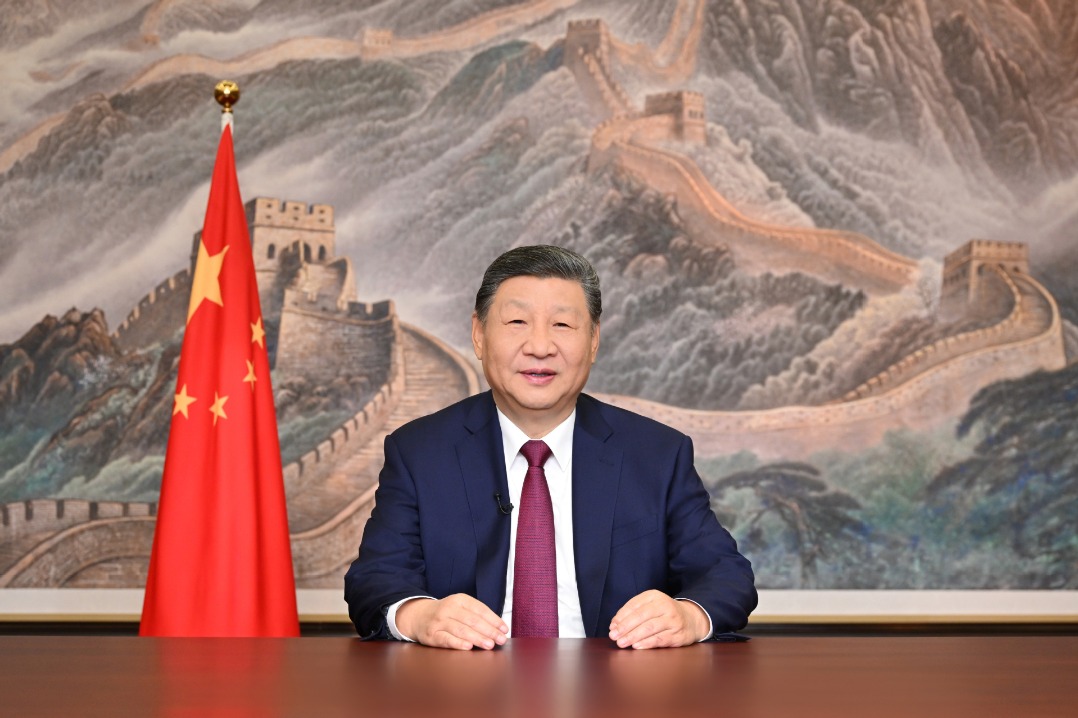

- Xi's message for New Year widely lauded

- New Year's address inspiring for all

- Xi congratulates Science and Technology Daily on its 40th anniversary

- Xi congratulates Guy Parmelin on assuming Swiss presidency

- China Daily launches 'China Bound'

- Manufacturing rebounds in December