Odds still give China an edge

Buoyant infrastructure, entrepreneurship spirit, huge market seen as compelling reasons

Rising costs, the yuan appreciation and an increasingly ageing population are prompting commentators and experts to suggest that China's long-term prospects as a manufacturing nation are in jeopardy.

Barring the most freakish of catastrophes this just won't happen and on the contrary, China's strength as a manufacturer will only increase in the coming decades.

The mix of what China makes and location of its manufacturing centers will change over a period of time. But there is no doubt that even in 2030 - or 2050 - China will continue to be a dominant manufacturing location, if not the most dominant.

The reasons for this are threefold: China's scale, especially of its markets; the infrastructure it has built and will continue to add to; and - most importantly - its entrepreneurial spirit.

China's markets will continue to be the seat of enormous government and consumer demand - something that will grow as the nation's prosperity increases. Manufacturers in almost every key industry from across the world will want to be present in China to take advantage of the huge demand.

Take the auto industry: It may have barely existed in China in the mid-1990s, but there is no way that international automakers, who have set up bases in the last 15 years, would want to leave the country now.

It is conceivable - even probable - that as China becomes more prosperous some industries may move to countries with cheaper land and labor costs. But in their place will rise other industries producing more valuable goods, both for sale in China and for export to overseas markets.

Ensuring China's rise as a manufacturing power has been its investment in infrastructure, clearly visible in its transport, energy and communications facilities. It will take decades for any other developing country to catch up with this spending.

Manufacturers in China are also supported by secondary industries made up of local and international suppliers and it does not make sense for large manufacturers to relocate to another country if suppliers and supply chain systems are not in place.

But also crucial has been China's investment in the soft infrastructure of a pro-business environment. Special economic zones, tax incentives, flexible labor laws and even a stable currency are all significant incentives that will continue to allow manufacturers to commit themselves, safe in the knowledge they can operate in a hugely pro-business environment.

Finally, there is China's entrepreneurial drive, possessed not just by its companies, but also by its government and population at large.

It is this enormous urge to succeed that makes doing business in China extremely competitive. In industry after industry, margins are low and only the most efficient and tightly run businesses can thrive.

But at the same time, this market freedom has led to a flood of investment, from both domestic and overseas sources, and stimulated an extraordinary range of innovation as companies look for new ways in which to outmaneuver their competitors.

The domestic companies that are emerging from this environment are some of the toughest - fast moving, lean and flexible.

To succeed in this market, multinationals are finding they have to bring ever more parts of their value to China - from research and development, to back-office functions, marketing and sales. Only in this way can they produce the goods their customers want at a cost in line with their ability to pay.

Clearly, neither Chinese nor foreign companies have plans to abandon the manufacturing operations they have started here.

So while China's business landscape is changing, manufacturing will continue to play an important role for decades to come. The combination of its market size, its modern infrastructure and its entrepreneurial drive will ensure that factories remain here for the foreseeable future.

The author is chairman of management consultancy Booz & Co in China.

Today's Top News

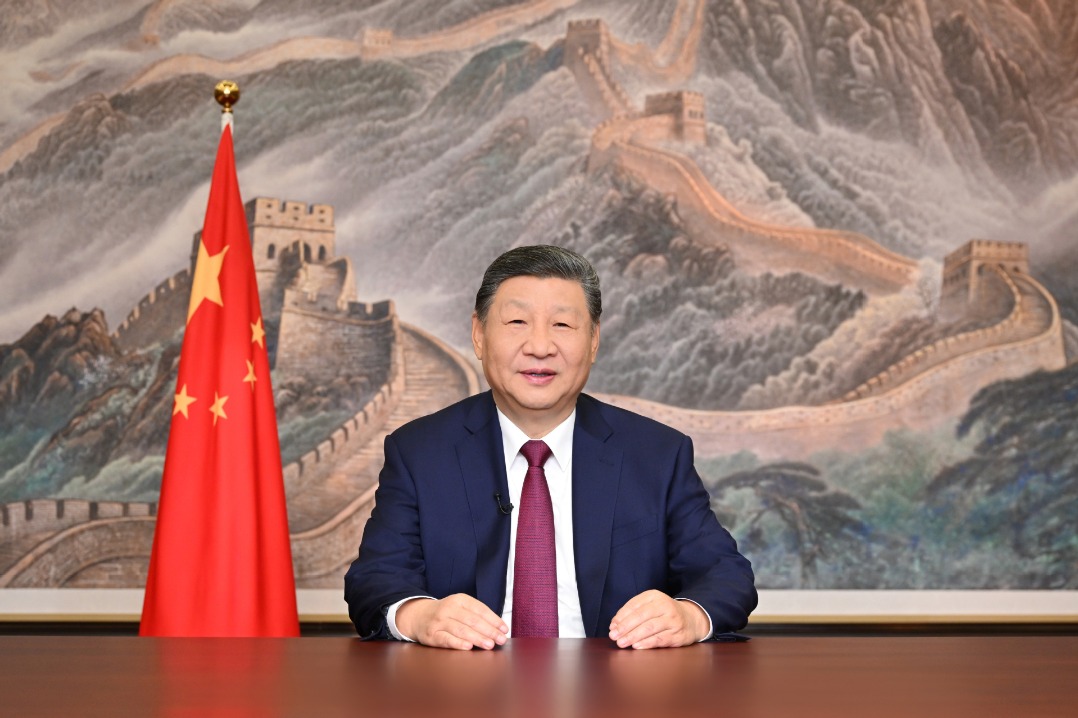

- New Year's address inspiring for all

- Xi congratulates Science and Technology Daily on its 40th anniversary

- Xi congratulates Guy Parmelin on assuming Swiss presidency

- China Daily launches 'China Bound'

- Manufacturing rebounds in December

- PLA wraps up military drills around Taiwan