Local automakers in midst of 'great leapfrog'

Borrowing from Germany's Industry 4.0 strategy, manufacturing is getting smart for the future

Chinese auto manufacturers are expected to build smart plants in the near future, though they remain one generation behind the world's leading carmakers in deploying Industry 4.0 technology.

Domestic brands are evolving in step with the application of electronics and information technology in automated production processes, or Industry 3.0, while Chinese government bodies are investing in the necessary infrastructure to catch up with the trend of data transfer in manufacturing technologies, according to insiders at the Global Automotive Forum in Chongqing.

| Welding robots work at a production line of JAC Motors in Hefei, Anhui province. Zhang Dagang / For China Daily |

Introduced in 2011 by the German government's working group, Industry 4.0 will see industrial production machinery no longer simply "process" products, but communicate with the products and each other to "understand" exactly what to do.

Deloitte Consulting (Shanghai) Co's automotive industry leader Marco Hecker says he believes local companies will have steeper learning curves, as he has witnessed many Industry 4.0 pilot projects in the country.

"Chinese carmakers are going to complete the deployment process of Industry 4.0 in less than two years, while their German counterparts took five years," Hecker said in an interview on June 8 on the sidelines of the forum.

"The Chinese government is helping the industry to grow through infrastructure," he says. "Many government departments have united together for quick decisions and faster action on essential investments.

"Industry 4.0 connects embedded system production technologies and smart production processes to pave the way to a new technological age that will radically transform industry and production value chains and business models," according to Germany Trade and Invest.

Deloitte Consulting wrote in a research report that Industry 4.0 represents an integration of the internet of things and physical technologies that complete the physical-to-digital-to-physical cycle.

The internet of things and new information technologies have been included in the nation's Made in China 2025 strategy launched in 2015, and the country is promoting the pilot applications of the internet of things and the integration of Internet Plus into the manufacturing sector.

Guo Gang, dean of the faculty of automotive engineering school at Chongqing University, sees the hurdle for the local sectors' leap toward smart production as described in Industry 4.0 literature.

"A smart plant is a huge and complicated system that involves many technologies in a very complicated way," he said. "The auto manufacturing industry won't accomplish it in one stroke."

Guo says a carmaker must find its specific starting point and application plan from that of the German automakers, as their current standing is behind that of their German counterparts.

"Chinese carmakers at this moment do not possess a thorough understanding of the (internet of things) or wireless communication technologies, and vice versa. Those IoT people don't understand auto manufacturing," Guo says.

Xu Daquan, Bosch (China) Investment's executive vice-president, shares a similar view on local car manufacturers, saying that they are working on Industry 3.0, as the majority of them are still "staying at a position between Industry 2.3 and 2.8".

"They are digitizing their plant through software and making progress in reducing the human resources involved in the production process," he says.

"It's a step-by-step process to digitize the entire product and connect the entire process to realize the idea of Industry 4.0."

He also believes it's possible for the domestic industry to overtake other countries, as Chinese carmakers may jump to Industry 4.0 on their way to 3.0.

"The great leapfrog requires the government's promotion and the industry's joint efforts," Xu adds.

Both Xu at Bosch China and Guo at Chongqing University agreed that people are the core of the deployment of Industry 4.0.

Xu believes Chinese automakers are in need of determined and ambitious experts to develop advanced concepts, pushing forward the companies and the entire sector for the next five to 10 years.

"People are the designers, managers and optimizers of Industry 4.0," says Xu.

haoyan@chinadaily.com.cn

(China Daily European Weekly 06/16/2017 page28)

Today's Top News

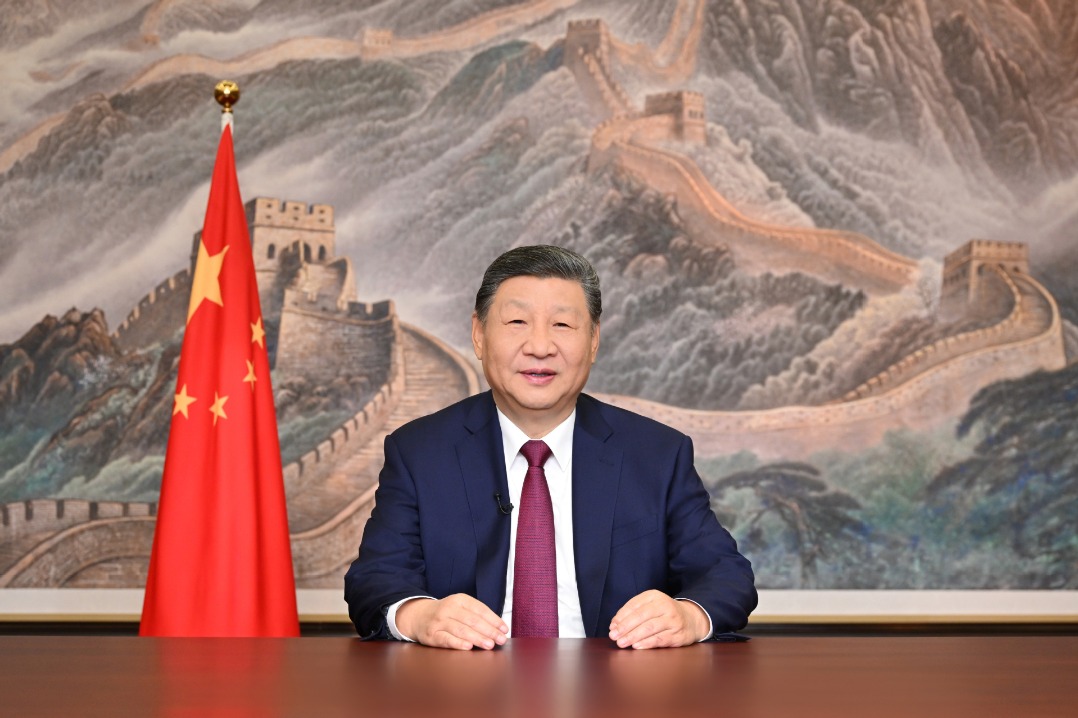

- Confidence, resolve mark China's New Year outlook: China Daily editorial

- Key quotes from President Xi's 2026 New Year Address

- Full text: Chinese President Xi Jinping's 2026 New Year message

- Poll findings indicate Taiwan people's 'strong dissatisfaction' with DPP authorities

- Xi emphasizes strong start for 15th Five-Year Plan period

- PLA drills a stern warning to 'Taiwan independence' separatist forces, external interference: spokesperson