3-D printing 'is booming'

China's many industries and fields use a well-developed ecosystem to embrace the new technology

Medical, automotive, machinery, consumer electronics, aviation, toys, home decor, even art - it appears there is no industry, sector or field of human endeavor in China that has not been touched by revolutionary 3-D printing technology.

Three-dimensional printing technology has helped create things like clothing, houses, sculpture, tumor models, machine parts and even drones.

Take, for instance, a patient who underwent brain surgery in Beijing recently.

The operation was unconventional, and almost like science fiction. Yet, it was real as well as successful.

In the end, the patient's brain was covered with ReDura, a 3-D-printed membrane, by experts at Peking University Third Hospital.

ReDura is a product of Medprin Regenerative Medical Technologies Co, a Guangzhou-based 3-D bioprinting company.

Yuan Yuyu, chairman of Medprin, says: "Brain surgery incisions used to be covered with membrane made up of animal-sourced materials, which exposes patients to risks of disease transmission.

"It also takes a long time for these animal tissues to be fully integrated into patients' own tissues, which prolongs suffering," he said.

ReDura, which is created using 3-D printers, is made up of biodegradable material.

Suffice it to say that it's magical, amazing and wonderful enough to be a worthy replacement for previous versions of the membrane.

No wonder ReDura has received the approval of the China Food and Drug Administration and gained acceptance in the European Union.

But ReDura is just the tip of the 3-D printing iceberg.

Chinese companies have made rapid advances in 3-D printing technology, whose formal name is additive layer manufacturing.

Progress spans both fundamental research and manufacturing techniques. Different from traditional manufacturing, which is based on the removal of material by cutting and drilling, 3-D printing creates objects by consistently laying down materials, such as wax, metal or polyurethane, based on virtual blueprints from computer-aided designs.

One impressive example in the aviation sector is the C919, China's first large passenger jetliner, which has 3D-printed components that help reduce its weight and shorten the delivery schedule. The plane made its debut flight earlier this year.

Wang Peng, secretary-general of the Additive Manufacturing Alliance of China, says that after years of development, 3-D printing is entering a new phase in China, from an innovative concept to something quite helpful in upgrading manufacturing plants, hospitals and even classrooms.

"3-D printing is booming. We have cultivated a relatively good industrial system, with manufacturing techniques close to, or on a par with, leading foreign countries. The sector is leaping from laboratory research into industrial applications," Wang says.

Last year, the output value of China's 3-D printing industry hit nearly 8 billion yuan ($1.2 billion; 1 billion euros; £931 million), up by 87.5 percent year-on-year and highlighting the strong momentum, according to date from the Additive Manufacturing Alliance of China.

Beijing, Shanghai and Shaanxi, Guangdong and Hubei provinces have formed a 3-D industry chain, in terms of geography, that covers product design, materials, key components, equipment and applications. Shaanxi province has applied for more than 1,000 patents related to 3-D printing.

"The technology represents the future direction of intelligent manufacturing, as it combines the advantages of large-scale production with personalized manufacturing. It is highly efficient and cost-effective," says Zuo Shiquan, a manufacturing expert at the Beijing-based China Center for Information Industry Development, a research institute affiliated with the Ministry of Industry and Information Technology.

China's 3-D printing industry is expected to reach $7.68 billion in output value, or one-third of the global market, by 2020, according to a forecast by the China Industry Information Institute.

The ministry is drafting a 2017-20 plan to accelerate the development of 3-D printing. It established the National Innovation Center by forging extensive partnerships between universities and companies. The idea is to help address technological bottlenecks that impede commercial applications.

Not surprisingly, companies such as Shining 3D Tech Co, a Hangzhou-based 3-D printing specialist, are optimistic about the sector.

Shining has already provided 3-D printing and scanning services to over 10,000 customers worldwide. Its clients include global corporate icons such as Intel Corp, Robert Bosch and Adidas.

Huang Xianqing, senior vice-president of Shining 3D, said 3-D printing can meet consumers' growing demand for environmentally friendly and personalized products.

The company has successfully applied its techniques to manufacture exhaust pipes for Ford cars. Different from traditional exhaust pipes, whose simple design can lead to bad air flow and huge power loss, the company's 3-D-printed pipes weigh 67 percent less. They can also help save energy.

Earlier this year, Shining partnered with US tech company Hewlett-Packard Inc to offer better 3-D printing services. The two sides will deploy hardware and software in 50 locations across China, including Beijing, Shanghai, Guangzhou, Chengdu and Nanjing.

It's not just high-tech or top-end segments that are embracing 3-D printing. In Beijing's suburban Huairou district, Chinese engineers in an economic and development park are scrambling to make 3-D printers that can produce household items.

The engineers are employed by about 300 companies in the zone, among which is Beijing Tiertime Technology Co, China's first exporter of 3-D printers.

Tiertime Tech sells tens of thousands of 3-D printers to more than 40 countries every year. Its 150-plus employees print products ranging from toys and cartoon figures to mobile phone shells and home decor.

Luo Jun, secretary of the World 3D Printing Technology Industry Alliance, says China needs to step up research and development on the "ink" for 3D printers (that is, material with stable qualities).

Contact the writers at masi@chinadaily.com.cn

(China Daily European Weekly 08/25/2017 page26)

Today's Top News

- Trump says 'a lot closer' to Ukraine peace deal following talks with Zelensky

- China pilots L3 vehicles on roads

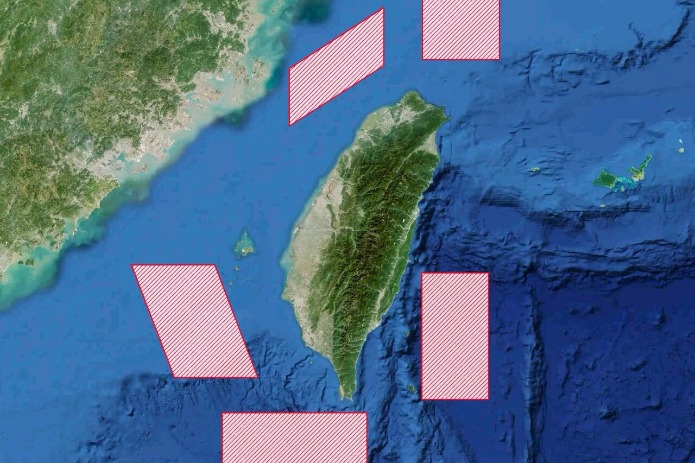

- PLA conducts 'Justice Mission 2025' drills around Taiwan

- Partnership becomes pressure for Europe

- China bids to cement Cambodian-Thai truce

- Fiscal policy for 2026 to be more proactive