Cruise ships to bolster high-end manufacturing

Homegrown vessels to create job opportunities, establish new supply chain and promote tech innovation in China

China has impressed the world with the construction of its high-speed railways and its first self-built large jetliner, and now the oceans are the next stage for high-end manufacturing as construction commences of the nation's first homegrown cruise ship, which is scheduled to be delivered in September 2023.

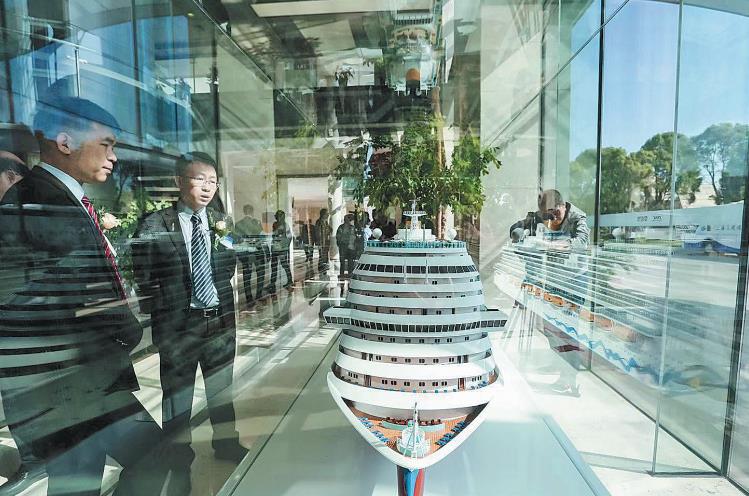

The 135,500-metric-ton Vista-class vessel will be built by Shanghai Waigaoqiao Shipbuilding Co Ltd, a company controlled by the China State Shipbuilding Corp. As a complex mega system project, it is completely different from the vessels Chinese shipyards have built.

"The greatest challenges will be safety and the supply chain," said Zhou Qi, vice-president of Shanghai Waigaoqiao Shipbuilding, who has been working in the shipbuilding industry for two decades.

Wu Xiaoyuan, head of the cruise ship project with Shanghai Waigaoqiao Shipbuilding, agreed.

"We could spend days talking about the hardships of the cruise liner construction process. To sum up, it involves bringing a gigantic entertainment complex from the land to the sea safely and in a timely manner, while keeping weight, running noise and costs under control," said Wu.

The Vista-class vessel, with a contracted price of $770 million, will have 2,125 passenger rooms to accommodate a maximum of 5,246 passengers as well as 700 crew rooms in its 323.6-meter-long, 37.2-meter-wide and 72.2-meterhigh body.

As Zhou described, the vessel will be a floating city equipped with the latest technologies to make passengers safe and comfortable, and make the vessel environmentally friendly and to reduce noise as much as possible.

Cruise ships are one of the most difficult types of vessel to build because they have higher requirements and standards in design, craftsmanship, operation and management, according to Wu.

Despite the efforts of major Asian shipbuilding countries including Japan and South Korea, European shipyards still dominate the global cruise ship building market.

In 2016, Japan's Mitsubishi Heavy Industries Ltd abandoned its ambition to build European cruise liners and shifted to smaller ferries and other medium-sized passenger ships due to cost overruns and delays in the construction of two 100,000-ton class cruise liners for Europe's Carnival Corp, Reuters reported.

According to Mitsubishi Heavy Industries, construction of the two vessels was plagued by faulty engines, late design changes and onboard fires, which resulted in a delay of more than one year and increased construction costs by nearly $2 billion, about four times the original cost.

"I think we should not be too confident in our own design and supply chain. The complexity of building a cruise vessel is unparalleled," said Zhou.

"In fact, the unsuccessful local supply chain played a part in Japan's serious delay and caused overruns," said Wang Yanguo, vice-president of CSSC Cruise Technology Development Co Ltd.

Building cruise vessels involves 25 million components and parts, more than 500 suppliers, and requires 12 million man hours. Its complexity even exceeds that of a bullet train, which requires hundreds of thousands of components and parts, or the C919 aircraft, which requires between 3 million and 4 million, according to Zhou.

Shanghai Waigaoqiao Shipbuilding imported 150,000 pages of design drawings and construction management documents from Fincantieri, weighing up to 2.1 tons.