How to make a good impression

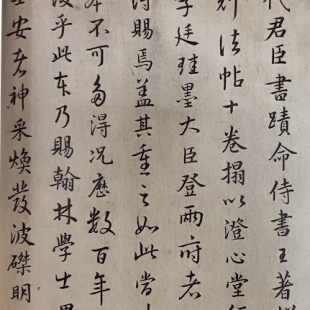

For any rubbing to be made of a piece of calligraphy, which in ancient China was often written on paper or silk, it has to be first inscribed into a stone slab or a hardwood board. Many details of that process remain unknown today, but one way of doing it involved putting a piece of semitransparent paper over the original writing so that the outlines of each character could be traced. The tracing would then be put onto the stone slab for the engraver to do his job.

In another recorded method, cinnabar was used to do the tracing from the back of the original writing. The paper was then put onto the stone, cinnabar side down. A few more layers of paper were added and a subtle grounding force applied from above, usually with a flat stone. The aim was for the minced cinnabar to stick to the stone surface, carrying with it the outline of brushstrokes that could be followed by the engravers.

Given the amount of engraving required to make big collections of model calligraphy, often undertaken by the government, this work could last for years, resulting in hundreds of inscribed stone slabs. Judging by the ones that are still in existence today, these stone slabs are usually rectangular, measuring about 1 meter in length and 30 centimeters in width.

It's also worth noting that on certain, although much rarer, occasions, a calligrapher could have directly written on a stone stele, often with red paint. In such cases, no transferring from the paper to the stone was required.

The actual process of completing a rubbing takes several steps. First, the inscribed surface is thoroughly cleaned, and a piece of moistened paper is plastered over it. An artisan would typically choose to use a sheet of thin rice paper, made of rice straw or other plant fibers, which is both strong and highly absorbent.

Then, the artisan gently forces the paper into all the incised areas — the engraved brushstrokes — with a broad brush. This is followed by the third step, whereby the artisan taps the paper with a mushroom-shaped pad, made of cotton and cloth and soaked with just the right amount of black ink. At the end of this step, while the main surface area of the stele is represented by the blackened paper, the incised parts of the stele remain blank, much like a photographic negative.

This approach is summed up perfectly in the Chinese term for rubbing — ta pian. Ta means to hit lightly or tap, and pian is a thin piece (of paper).

At last, after the paper has dried properly, it is carefully peeled off the stone surface, a tactile impression of the original piece of calligraphy.

Simple as it may seem, producing calligraphy rubbings that were able to convey the delicacy and dynamism of each brushstroke would most likely be fastidious, backbreaking work for the master engravers, and would certainly require the close attention of an experienced artisan who saw their job as not merely making copies, but re-conjuring the magic interplay between ink and paper.

However, with the arrival of collotype, a photomechanical flat printing process that is able to produce varying tones and shades, in the early 20th century, rubbing quickly started to lose its foothold. Amid all the political turmoil that enveloped China at the time, including the fall of the Qing Dynasty in 1911, rubbing, not unlike many other forms of traditional arts, was no longer in demand, and therefore was fast receding into the back of people's collective memory.

Today, many secrets of the art — special techniques, tools and pigments for example — that were once heavily guarded by their practitioners and were routinely passed only from a master to his few apprentices, are likely to remain forever a mystery.