Equipment key to new quality productive forces

The development of critical technical equipment, such as advanced machine tools and subway trains equipped with permanent magnet traction systems, will be instrumental in supporting China's plan to cultivate new quality productive forces, national legislators and political advisers from State-owned enterprises said.

According to this year's Government Work Report, China will strive to modernize its industrial system and accelerate the development of new quality productive forces.

The country will undertake technological transformations and upgrade its manufacturing sector, create advanced manufacturing clusters, and establish national demonstration zones for new industrialization. These efforts are aimed at transforming traditional industries to become more high-end, intelligent and environmentally friendly, according to the report.

Critical technical equipment is crucial to the national economy and strategic security, serving as a key support for industrial upgrading and technological advancement, said Zhang Xiaolun, a member of the 14th National Committee of the Chinese People's Political Consultative Conference.

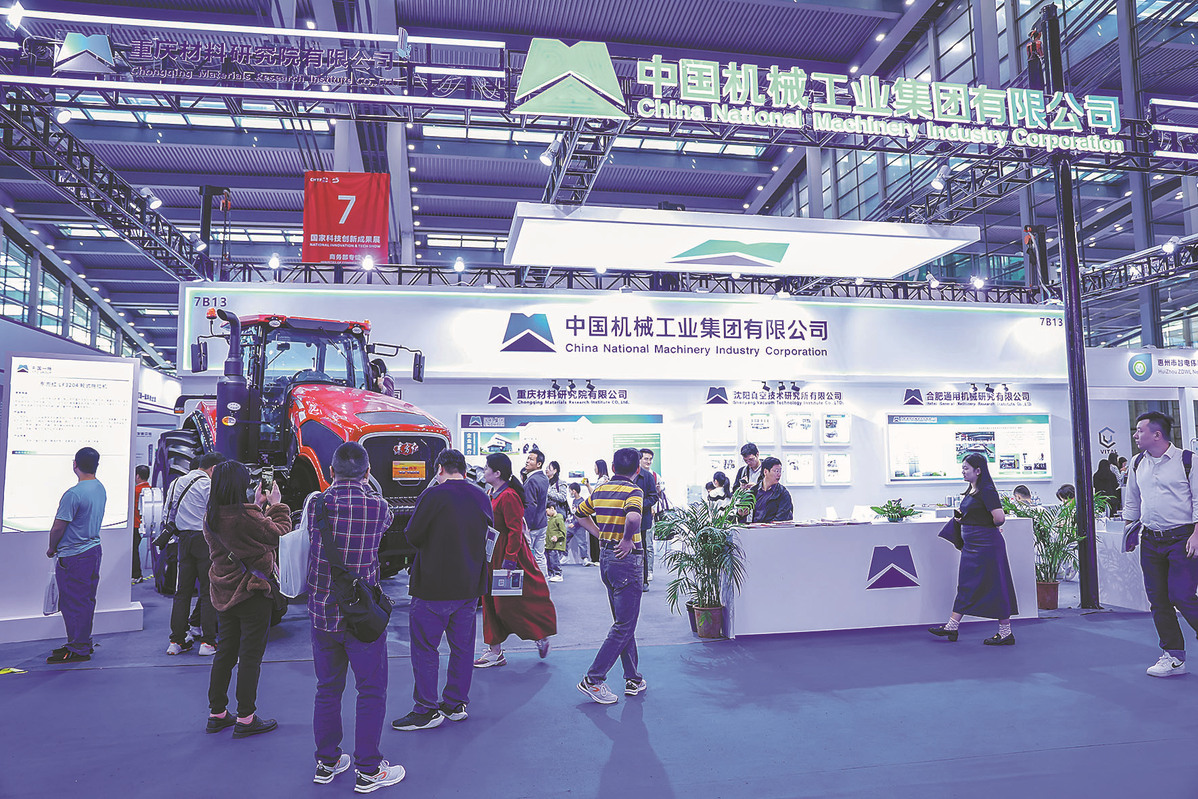

Zhang, who is also board chairman of China National Machinery Industry Corp, a Beijing-headquartered centrally administered State-owned enterprise, said the widespread application of such equipment will generate a significant pull effect on the upstream and downstream industrial chains, playing a crucial role in driving the development of new quality productive forces.

Emphasizing the feasibility of China creating a hub for cutting-edge technology in the machine tool industry, he said that it is essential for the country to step up efforts to promote machine tool products and build a comprehensive industrial ecosystem to speed up the progress of industrial technology and modernize the industrial chain in the machine tool sector.

With China entering a new era of green and innovation-led growth, Sun Yongcai, another member of the 14th National Committee of the CPPCC, said Chinese companies have already achieved breakthroughs in new technologies, including permanent magnet traction systems and silicon carbide conversion.

These technologies have the advantages of high efficiency, energy saving, environment protection and high reliability, and are the foundation for large-scale application and promotion, said Sun, who is also board chairman of CRRC Corp.

CRRC is the world's largest supplier of rail transit equipment with the most complete product lines.

According to the company's statistics, 55 Chinese cities operated urban rail transit systems covering 10,165 kilometers by the end of 2023. The annual electricity usage is about 22.79 billion kilowatt-hours, resulting in around 19.35 million metric tons of CO2 emissions.

By implementing these new technologies, the annual electricity consumption of China's urban rail transit system could be reduced by 24.8 percent, leading to savings of 5.65 billion kWh and a cut of 4.8 million tons in CO2 emissions.

He suggested that local governments and relevant operators prioritize and fully utilize new technologies while purchasing new subway carriages. This will facilitate the green transformation and hardware upgrade of China's urban rail transit system.

Zhu Huarong, a deputy to the 14th National People's Congress, also expressed similar views.

"The development of new energy vehicles has become a global consensus for green transformation. Chinese manufacturers need to further consolidate their accumulated advantages to lay the foundation for creating competitive global brands."

Zhu, who is also board chairman of China Changan Automobile Group, stressed that the auto market's future will be characterized by diverse and differentiated competition in the medium and long term. Intelligent driving presents a significant opportunity, with scale and cost advantages being crucial for success, Zhu added.

In the meantime, automakers will evolve from being mere vehicle manufacturers to becoming data-driven and tech-savvy companies, he added.

By 2030, the State-owned automaker will invest 200 billion yuan ($27.78 billion) to position itself as a front-runner in the era of "smart new vehicles".