From steel to railways, big AI models transforming industries across nation

The application of large artificial intelligence models is transforming sectors across China, including Hebei province's traditional steel industry, driving significant efficiency gains and cost reductions. As AI reshapes industrial production, the trend is drawing widespread attention from grassroots lawmakers and political advisers nationwide.

Xinxing Ductile Iron Pipes Co, a major iron and steel producer in Wu'an, Handan city, has implemented 38 AI-driven application scenarios since 2023. Among them is a coal blending model that has reduced the cost of each metric ton of coke by 9.4 yuan ($1.30), according to Wen Zhihui, head of the company's digitalization department.

"The ratio of using different types of coal from various manufacturers directly affects the quality and cost of coke," Wen said.

Previously, coal blending schemes required experienced supervisors to formulate plans based on the composition and price of each coal type, relying heavily on trial and error and subjective judgment.

"This process involved numerous trials, and slight negligence could lead to fluctuations in coke quality or increased costs," Wen said.

In 2023, Wen's department developed two AI-driven calculation models using big data to determine optimal coal blending ratios, achieving a more precise and scientific process.

"We input quality parameters into the models, which conduct billions of calculations before selecting 10 blending schemes that meet quality standards at the lowest cost," he said.

The company's use of AI reflects a broader push across Hebei, a major steel hub, to integrate AI models into steel production.

According to the Hebei Metallurgical Industry Association, key steel enterprises in the province produced approximately 200 million tons of crude steel last year, accounting for about 20 percent of China's total crude steel output.

"Steel is a pillar industry of Hebei. We will organize universities, research institutions and enterprises to further develop large AI models for the steel industry, empowering innovation with advanced technology," said Wang Hefu, an official with the province's industry and information technology department.

At the end of last year, HBIS Group Co, a leading steel producer headquartered in Shijiazhuang, developed the WeShyper Iron and Steel Large Model, an advanced AI system designed for the steel industry. The model integrates language understanding capabilities and efficient algorithms to streamline information processing, decision-making and operational management in steel production.

"We have identified 142 AI scenarios with implementation potential and development value to enhance 12 industrial procedures with digital intelligence," said Xu Min, director of the bureau of data technology and industrial informatization in Qian'an, Tangshan city, as quoted by Hebei Daily.

Since last year, Qian'an — a key player in Hebei's steel sector — has been working with 39 steel enterprises and 13 top domestic AI firms to develop AI application models for steel production. Together, they have established the Hebei Taihang Steel AI Management System to address challenges in steel production using AI.

AI adoption is accelerating across industries nationwide. From healthcare to finance and ports to railways, AI is driving innovation and improving efficiency.

Deputies to this year's upcoming National People's Congress are advocating for continued AI development and application in their respective fields.

Shao Lili, a deputy from Jinan, Shandong province, will focus on AI and big data research and applications when the annual congress session convenes in March, according to a report by Xinhua News Agency.

Shao, who specializes in railway informatization project construction and information system development, has led a research group focusing on AI, digital twins, the internet of things and big data to support the intelligent construction of railways and smart passenger travel.

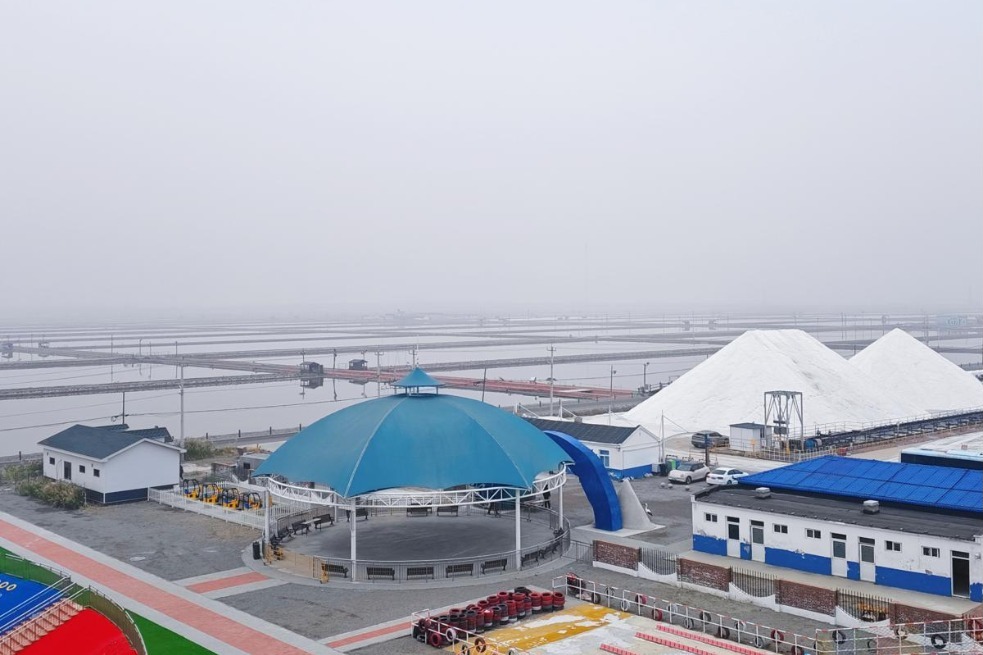

AI is also transforming port operations. Cheng Weidong, a deputy to the congress from Tianjin and an employee of Tianjin Port, has been closely following the digital transformation of traditional ports.

"As the team leader of AI trainers at Tianjin Port, I have gained a new understanding of how traditional industry workers integrate with cutting-edge technology," Cheng told Economic Daily on Monday.

zhangyu1@chinadaily.com.cn

- Xi's special envoy attends inauguration of Bolivian president

- Countdown to 15th National Games: On-site warm-up entertains audience

- Eight missing after cargo ship collides with fishing vessel near Shandong

- Investing in people: a worthwhile investment

- Exhibition commemorating the epic relocation of universities opens in Fujian

- Twelve punished for scaffold collapse that killed 7 in Shandong