How China's EV industry has become an innovation champion

When I stepped into NIO's advanced manufacturing factory in Hefei, capital of East China's Anhui province, it didn't feel like a typical car plant. There was no deafening noise. Instead, it felt like a human brain — alive aware, and impossibly efficient.

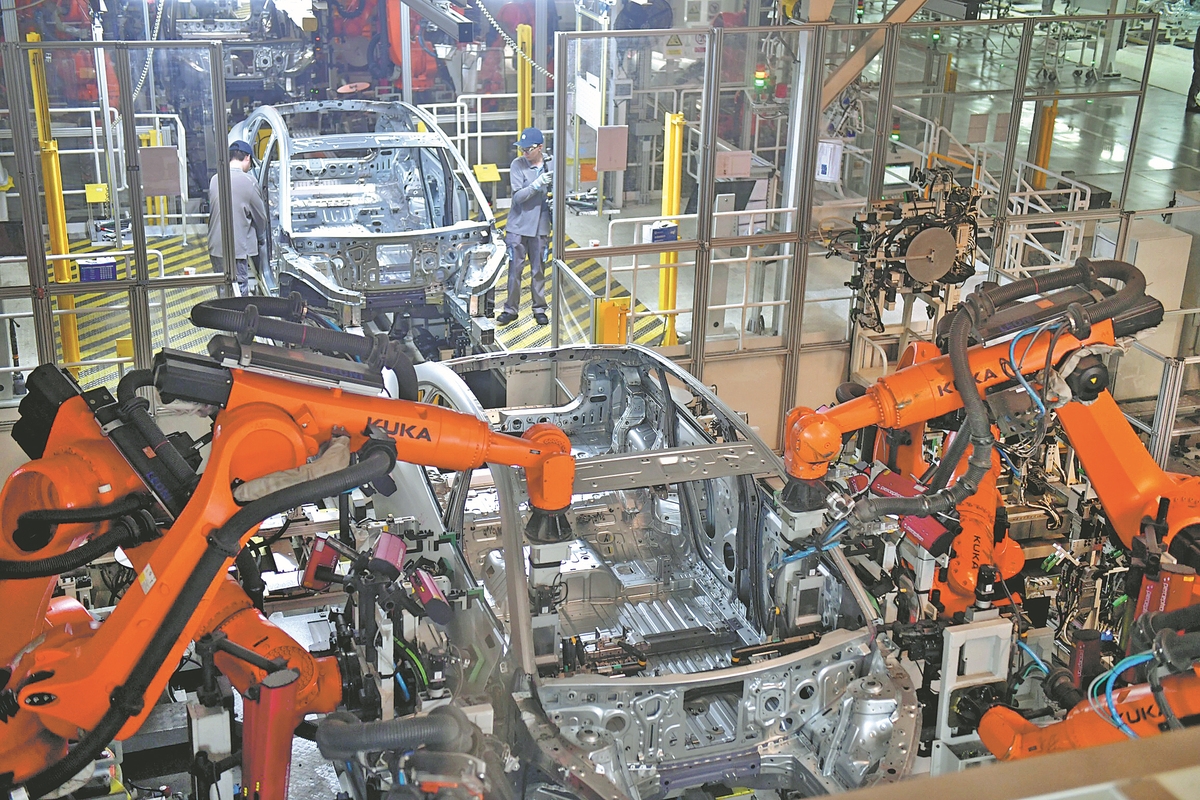

Robots moved in elegant synchrony. Screens glowed with real-time data. Parts of the plant run in total darkness. NIO calls it "black light" manufacturing.

I came to Hefei expecting a factory tour. What I found was something much bigger: a glimpse into how China's electric vehicle industry is not only surviving, but leading the global transformation.

NIO's founder and CEO Li Bin met us. Wearing a polo T-shirt and sneakers, he looked more like an engineer than a tech tycoon.

"I live in Shanghai. Coming to Hefei is really convenient. This week, I'll be here three times. It's already become a kind of commute," he said.

In 2020, NIO was in what Li called the "ICU". Cash-strapped and on the brink, the company needed a lifeline. That lifeline came from Hefei.

The city government stepped in with investment, land and unwavering support. NIO didn't just survive, it built a new headquarters, established world-class research and development, and launched one of the most advanced manufacturing hubs in China.

"This," Li gestured around the sprawling facility, "is the result of mutual trust. Government and enterprise running toward each other."

Inside the factory, 941 robots work across the production line. They don't just assemble, they think. At every stage, AI systems guide quality control, manage complexity and optimize speed. I watched as an entire car body was lifted, welded and precision-inspected without a single human hand touching it.

But as impressive as the hardware is, what struck me more was the software of collaboration, the invisible yet powerful network that binds everything together.

Around the factory, NIO's key suppliers have also built facilities. In fact, several are connected by enclosed corridors that allow parts and components to move between companies without trucks or delays.

This is symbiotic manufacturing. Suppliers and automakers don't just coexist — they codesign, co-plan and co-invest. They share cost targets. They agree on quality benchmarks. They innovate together.

And they do it fast.

"It's not just about us anymore," Li said. "This whole area is becoming an ecosystem. What we built with Hefei isn't just a factory — it's a platform."

That platform is a sprawling smart EV industry park codeveloped by NIO and the city of Hefei. It's already home to two complete vehicle factories, plus a growing community of partners. In the three years since breaking ground, NIO's network of suppliers in Anhui has more than doubled.

I walked through the final inspection area, where an AI-powered scanner runs a full-body diagnostic on every car in just three minutes.

Over a thousand parameters are checked with 99.7 percent accuracy. Another system manages the factory like a real-time brain — adjusting workflows, tracing every part and eliminating bottlenecks. Nothing escapes its notice.

The innovation doesn't stop at production.

NIO's swappable battery stations — now numbering over 3,300 nationwide — let users "refuel" in three minutes. That's faster than pumping gas. It's a bold bet, but it's working. Other Chinese automakers, from Geely to Changan, are now joining NIO's open battery-swap alliance.

I left the factory that afternoon with a kind of whiplash — not from speed, but from perspective. In a world where many EV players are struggling to scale, NIO is building something deeper — an industrial ecosystem, a technology stack, and a service loop that spans the entire vehicle life cycle.

And Hefei, once a lesser-known inland city, is now firmly on the world's EV map.

From ICU to innovation hub in just four years, NIO had seen it all.

As Li said before heading into his next meeting: "I believe in China's ability to lead this global shift. We've got the speed, the vision — and now, the systems to back it up."