'Eco stars' exemplify industry, nature can coexist in harmony

SHENYANG — A flock of sheep graze lazily on green grass as geese waddle by in a scene that could easily be mistaken for a meadow in the Chinese countryside.

But the setting is far from rural. The animals live on the grounds of Michelin's tire factory in Shenyang, which was once a gritty heavy industry stronghold in the northeastern province of Liaoning.

What began with three sheep brought in to replace chemical weed control in 2022 has since grown into a flock of 24, now affectionately dubbed the facility's "eco stars". Their grazing keeps the grass trimmed, their droppings fertilize the soil and their presence has become a symbol of how industry and nature can thrive side by side.

"We are trying to build a green space where industry and ecology coexist in harmony," said Li Yanbing, general manager of Michelin Shenyang Tire Company.

This unusual pairing of animals and tires is part of a broader story. Across China, factories are trading smokestacks and chemical fumes for clear sky and clean air in a sweeping green industrial transformation that is reshaping the landscape of the nation's manufacturing heartland.

A few hundred kilometers away from the tire plant on Changxing Island in the harbor city of Dalian, the sun glints off tanks and pipelines across Hengli Petrochemical's sprawling industrial park — a giant fortress of steel that looks every bit the picture of heavy industry and was long criticized as energy-hungry, polluting and resource-intensive.

Yet inside its wastewater treatment exhibition hall, the sights are unexpectedly serene: koi fish swim under bridges and clean recycled water flows beneath luxuriant vegetation.

"This water's chemical oxygen demand is below 15 milligrams per liter, far better than the national standard," said the company's general manager, Xu Jin, clearly proud of a system that makes waste treatment a part of the scenery.

China has remained the world's largest manufacturing country for 15 consecutive years. But in very recent years, the rapid advance of smart manufacturing and a wave of green innovations have transformed many of the country's once-smoky, soot-stained plants into places that look more like landscaped parks.

In Tiexi district of Shenyang, formerly the center of that industrial powerhouse, sprawling factory zones are now home to attractions like the Tiexi plant of BMW Brilliance, which has become an industrial tourism site.

On its grounds stand rows of trees, landscaped gardens and an artificial lake where egrets perch and koi fish glide gracefully through the water.

Through ecological planning and restoration, the plant has created a workplace that blends seamlessly with nature. Its green space spans 380,000 square meters, and since 2017, it has welcomed over 130,000 tourists.

And more garden-like green factories could be on the horizon.

By January 2025, the output of China's national-level green factories accounted for about 20 percent of the country's manufacturing value, according to official data. The government's goal is to push that share of green factories above 40 percent by 2030.

On factory floors, China's green shift is no longer an abstract policy goal, it is tangible, measurable and increasingly profitable.

Northeast Pharm, a leading drug maker based in Shenyang, offers a good example.

The company has revamped its production lines with closed-loop systems that keep dust out of the air and capture emissions before they spread. "We've achieved sealed material feeding, material transfer and centrifuging," said Zhao Zhiyuan, deputy director of a plant that operates under the company. "The use of raw materials has since been reduced while pressure on pollution treatment has been cut significantly."

Outside the company's vitamin C workshop, a recovery unit collects low-concentration methanol and converts it into carbon sources, which are then reused in wastewater treatment to remove pollutants.

The system saves 620 metric tons of methanol each year, turning once discharged pollutants into reduced costs of 1.48 million yuan ($206,200), according to Zhao.

"What used to be a burden is now a profit source," Zhao said. "Environmental protection is not a cost, it's competitiveness now."

In Shandong province, Chinese heavy-duty truck manufacturer Sinotruk is reaping similar rewards.

Sinotruk exported 134,000 new energy heavy-duty trucks in 2024, worth a total of 44.9 billion yuan. Liu Peng, who works for Sinotruk's international arm, attributes the outstanding performance in the African and Southeast Asian markets to the company's green transition.

"African clients care about carbon emissions very much," said Liu. "Our pure-electric heavy-duty trucks are over 15 percent more energy efficient than European brands."

At its Laiwu plant, the transformation is visible from above. Rooftops covered with solar panels generate 260,000 kilowatt-hours of electricity each day, which is well beyond the 170,000 kWh the factory consumes daily.

The solar panels on the rooftops are part of the company's two photovoltaic power stations, which cut carbon dioxide emissions by nearly 40,000 tons each year.

Nationwide, the results are adding up. In 2024, China's energy consumption per unit of GDP was 11.6 percent lower than in 2020, equivalent to reducing carbon dioxide emissions by 1.1 billion tons. That has made China one of the countries with the fastest decline in energy intensity in the world.

"China is accelerating the construction of a green, low-carbon and circular economy," said Zhou Haibing, deputy director of the National Development and Reform Commission. He noted that the country has nurtured more than 6,400 national-level green factories and over 490 green industrial parks.

"From going green because we must to because we want to, China's factories have been redefining their role in recent years," said Bi Deli, a professor at Liaoning University.

For decades, growth and sustainability seemed at odds. Now, China's green factories are trying to prove they can be partners and turn sustainability into a source of strength, Bi noted. "It's an important insight that China's manufacturing industry offers for the global industrial transition toward low-carbon development."

Xinhua

Today's Top News

- China to apply lower import tariff rates to unleash market potential

- China proves to be active and reliable mediator

- Three-party talks help to restore peace

- Huangyan coral reefs healthy, says report

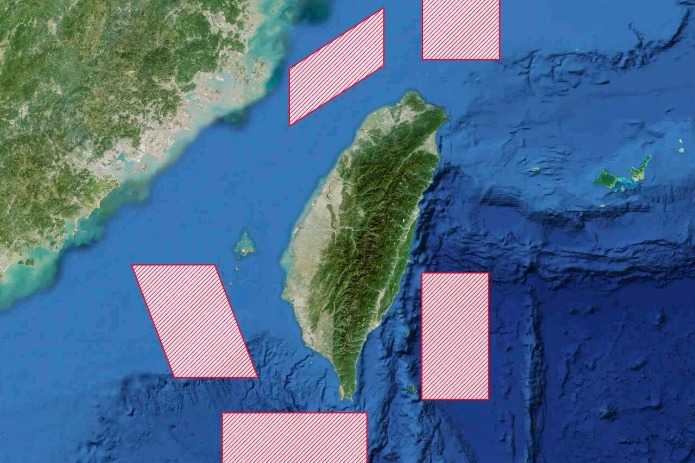

- PLA conducts major drill near Taiwan

- Washington should realize its interference in Taiwan question is a recipe it won't want to eat: China Daily editorial