Calls for greater push on high-end manufacturing

|

|

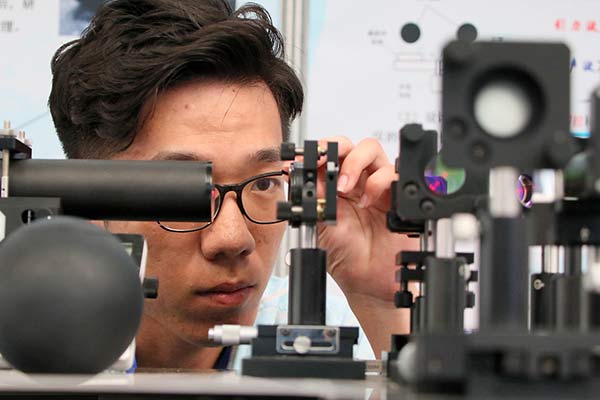

A technician introduces how a robotic arm works at a machinery expo in Harbin, capital of Heilongjiang province.[Photo/Xinhua] |

China will step up efforts to boost high-end and intelligent equipment manufacturing, and accelerate innovations in sensor and control system as well as industrial software to upgrade the country's traditional industries, said Xin Guobin, vice-minister of Industry and Information Technology.

"The major direction of the Made in China 2025 strategy is intelligent manufacturing, with a key issue of applying more sensors, industry control systems and an industry internet system to realize intelligent decision-making," Xin said, adding efforts in this regard should be strengthened.

"We will continue to promote the development of high-end numerical control machine tools, basic manufacturing equipment, domestically developed planes and other important technical innovation projects."

Xin said the ministry will carry out major equipment projects in areas where the country is at a disadvantage, mainly supporting engineering and industrialization projects that were required to boost innovation in key areas to transform traditional industry.

The ministry will also expedite the construction of manufacturing innovation centers for advanced materials and robotics, and press ahead with the formulation of industrial internet strategy-as well as establishing a number of industrial internet platforms, according to Xin.

"The country attaches great importance to intelligent manufacturing, as 70 percent of intelligent equipment and components are imported," said Qu Xianming, an expert with the National Manufacturing Strategy Advisory Committee, who is also an analyst at the Chinese Machinery Industry Federation.

The Made in China 2025 strategy, designed to upgrade China's manufacturing capability, set a target that 40 percent of core equipment components and key infrastructure material will be China-made by 2020, with an increase to 70 percent by 2025.

Qu added with the ever-increasing demand from domestic consumers, companies must produce high-quality products to satisfy their requirements, adding that robotics was a sector related to intelligent manufacturing.

Siasun Robot and Automation Co Ltd, a major robot maker in China, said it is making great efforts to launch a new generation of robots, which could achieve communication between humans and machines.

The company said it has independently developed control panels, although speed reducers, servo motor are imported. In 2014, Siasun established a subsidiary engaged in producing core components for robot manufacturers, expanding to the upstream of the industrial chain.