Expo highlights smart auto ecosystem

From AI-powered assembly lines and driving experiences to a surge in cross-border collaboration, nation's automotive sector embracing interconnected future

BEIJING — Every few dozen seconds, a gleaming electric vehicle glides off an automated assembly line in China, where nimble robotic arms perform with ballet-like precision and AI systems orchestrate production with flawless efficiency. This scene may have once been limited to flashy demo clips, but it is now the new reality of China's booming auto industry.

China, the world's largest automobile market, is moving into high gear.

What's powering this transformation stole the spotlight at the third China International Supply Chain Expo (CISCE).

"The EV industry in China in the last five years is probably the most surprising (development) to the world," said Jensen Huang, CEO of US tech giant Nvidia, which supplies in-vehicle chips to Chinese EV makers including Xiaomi, Geely, XPeng and Li Auto, during an interview on the sidelines of the expo.

In the first half, new-energy vehicle (NEV) production and sales surpassed 6.9 million units, up more than 40 percent year-on-year, said the China Association of Automobile Manufacturers (CAAM). Exports soared 75.2 percent during the same period.

Beyond the impressive statistics lies a deeper revolution. From AI-powered assembly lines and AI-supported driving experiences to a surge in cross-border collaboration, China's automotive sector is embracing a smarter and more interconnected future.

"Leveraging the world's largest auto market, China has developed a dual engine of tech innovation and commercial scale," said Zhang Yejia of CCID consulting under China's Ministry of Industry and Information Technology. "Electric, smart, and connected — new ideas are validated faster here."

Unlike traditional trade fairs that primarily focus on goods or services, the CISCE has introduced an innovative "chain-centric" model that emphasizes end-to-end industrial collaboration. This approach is especially pronounced in the automotive sector, renowned for its lengthy and complex supply chains.

In the hall showcasing integration of the auto sector, upstream, midstream and downstream companies cluster in adjacent booths, visually demonstrating their interdependence. Even amid the array of products dazzling eager audiences and professional attendees, US EV giant Tesla's Model Y still garnered much attention.

This top seller in the competitive Chinese EV market exemplifies how global players are thriving in China's smarter, more dynamic auto ecosystem. Tesla has achieved a stunning 95 percent localization rate for the components of this model. At its iconic Shanghai Gigafactory, a completed vehicle rolls off the production line every 37 seconds.

"China possesses the world's most complete EV industry chain," said Tao Lin, vice-president of Tesla. "Supported by a vast talent pool, China's strong track record in EV development, advanced manufacturing and AI provide unparalleled support and opportunity. We will continue to deepen our investment here," Tao said.

As of June 2025, Tesla has delivered more than 8 million electric vehicles globally, with nearly half of that production coming from its Shanghai Gigafactory.

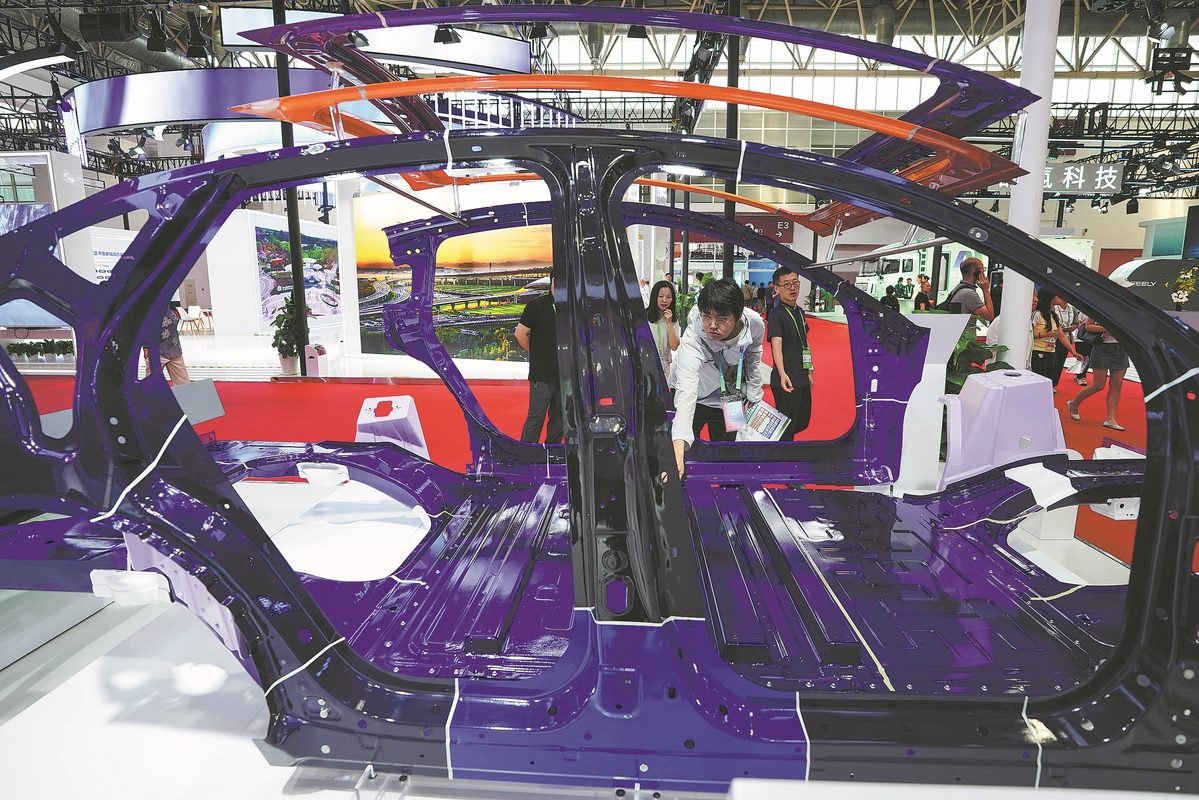

Just steps away from the US EV maker's booth, a gleaming car body from Chinese automaker Nio draws attention — not for its curves, but for the massive robotic arm hovering beside it.

Suspended from the arm is a lightbox-like 3D deflection camera, which sweeps methodically across the painted surface. Within a minute, a digital 3D model of the vehicle, complete with highlighted paint flaws, appears on a nearby screen.

The system, known as PaintPro, was developed by Changsha-based Speedbot Robotics and is already in use by several leading Chinese automakers. It fuses AI with 3D vision technology to detect surface defects as small as 0.15 millimeters, setting a new benchmark for precision in automotive quality control.

"This fusion of AI and vision technology addresses a long-standing industry pain point," said Ge Junhui, an engineer with the company. "Automotive paints, prized for their high gloss, are notoriously difficult to inspect using traditional machine vision, which often falters under reflective surfaces."

As a result, many manufacturers have long relied on manual inspections, a slow, labor-intensive process susceptible to inconsistencies. "Our solution helps automate one of the last strongholds of human-led quality assurance," Ge added.

Meanwhile, an increasing number of automakers are bringing AI from behind the scenes to the center stage, turning its capabilities into standout features that consumers can see, feel and experience firsthand.

One of the notable trendsetters is Guangzhou-based XPeng, which has laid a solid foundation for the AI revolution through its early deployment of AI across many product forms.

"The next decade of the auto industry will be defined by the convergence of automobiles and AI," said He Xiaopeng, chairman and CEO of the automaker, earlier this year.

At the company's booth at the CISCE, the spotlight is on its newly launched G7 model, which features its self-developed Turing AI chips and an AR-HUD system codeveloped with Huawei. According to the company, these advanced chips will enable the G7 to support Level 3 autonomous driving.

The model also features an AI-supported chassis that scans road conditions 1,000 times per second and makes adaptive suspension adjustments, supporting early detection up to 200 meters ahead and lane-level bump perception and recording.

"From intelligent driving and smart cockpit to flying vehicles and AI robots, we see each as a unique scenario powered by the same underlying tech stack," said He. "I believe AI and energy technology will distinguish us from competitors over the long run."

Xinhua